Relay boards are essential components in various industrial applications, controlling the flow of electricity to different circuits. When these crucial devices malfunction, it can lead to costly downtime and production delays. However, with the right knowledge and approach, you can troubleshoot and repair a relay board like a pro!

Here, we will walk you through some valuable tips to tackle relay board issues effectively, ensuring smooth operations for your industrial systems.

Understanding the Basics

Before diving into the troubleshooting process, it's vital to have a solid understanding of how relay boards work. A relay is an electromechanical switch that uses an electromagnet to open or close circuits. This allows low-voltage control signals to switch higher-voltage loads. Familiarize yourself with the different components of the relay board, such as the coil, contacts, and terminals. This foundational knowledge will help you pinpoint potential issues more effectively.

Safety First

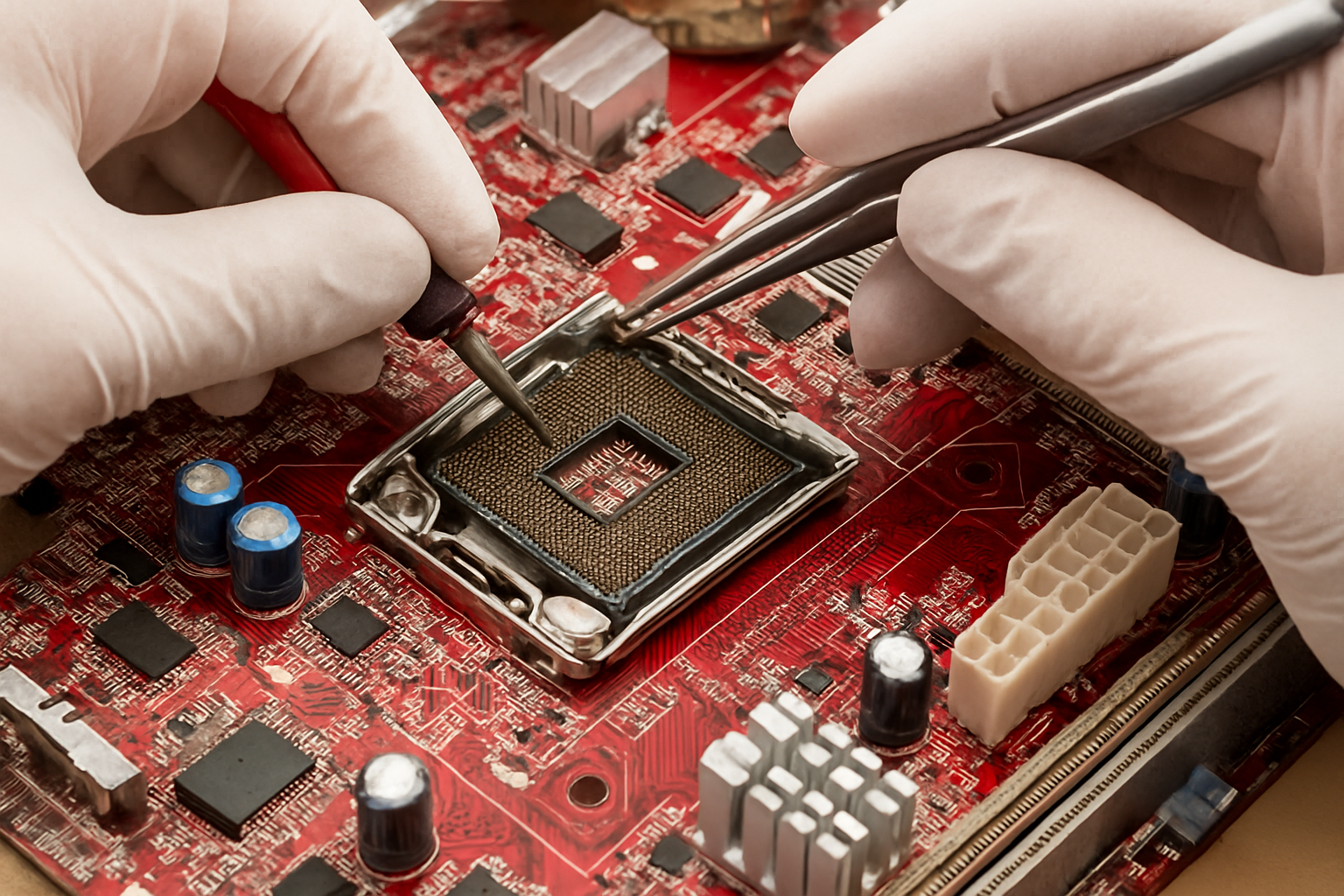

Working with electrical components poses inherent risks. Always prioritize safety while troubleshooting and repairing relay boards. Before you start, ensure that the power supply to the equipment is disconnected and that the board is discharged. Wear appropriate personal protective equipment (PPE) like gloves and safety goggles to minimize the risk of injury.

Visual Inspection

Start the troubleshooting process with a thorough visual inspection of the relay board. Look for any signs of physical damage, such as burnt or melted components, loose connections, or corrosion. Check for damaged traces on the circuit board. Identifying visible issues can often lead you straight to the source of the problem.

Testing the Coil

The coil is the primary element responsible for activating the relay. Using a multimeter, test the coil's resistance to ensure it falls within the specified range. If the resistance is too high or too low, it may indicate a faulty coil that needs replacement.

Checking the Contacts

Relay contacts can become worn or pitted over time, leading to connectivity issues. To check the contacts, use a multimeter in continuity mode. When the relay is not energized, the contacts should be closed, and when energized, they should open. If the contacts do not change state as expected, they may need cleaning or replacement.

Coil Voltage Verification

Verify that the coil is receiving the correct voltage when energized. An inadequate or excessive voltage supply could be the reason for the relay malfunctioning. If the voltage is incorrect, trace the circuit to find the source of the problem, which could be a faulty power supply or a control signal issue.

Cleaning and Maintenance

Dirt, dust, and debris can accumulate on relay boards over time, affecting their performance. Regularly clean the board using compressed air or a soft brush. Avoid using harsh chemicals that could damage the components. Additionally, consider using a conformal coating on the board to protect it from environmental contaminants.

Replacement Parts

If you identify faulty components during your troubleshooting process, make sure to use high-quality replacement parts. Using original manufacturer parts or certified alternatives will ensure the relay board's optimal performance and longevity.

Seek Professional Assistance

Sometimes, troubleshooting complex relay board issues may require specialized knowledge and equipment. If you encounter difficulties during the process, don't hesitate to seek professional assistance from experts like Melriya Technical Solutions L.L.C. Melriya specializes in servicing industrial products from various renowned companies like ABB, Siemens, Allen Bradley, and many more, ensuring reliable solutions for your relay board repairs.

Preventive Measures

Once you've successfully repaired the relay board, implement preventive measures to avoid future issues. Regularly inspect and maintain your equipment to detect and address potential problems early on. Implementing a preventive maintenance schedule can significantly reduce downtime and costly repairs.

To Conclude..

Troubleshooting and repairing relay boards require a systematic approach and a good understanding of the components involved. Follow safety guidelines, perform visual inspections, and use a multimeter to test the coil and contacts. Clean and maintain the relay board regularly, and if needed, seek professional assistance from reputable service providers like Melriya Technical Solutions L.L.C.

By following these tips, you can repair a relay board like a pro and ensure smooth operations in your industrial systems. Remember, a well-maintained relay board is the key to efficient and reliable industrial processes.

.png)

.jpg)